Work in progress.

Two-stroke motorcyle history.

The Future - the new breed of two-strokes.

Orbital Direct Injection.

Officially called FlexDI Air Assisted Direct Injection is the pioneering invention from the Australian Orbital Engine Company.

Comparison figures for Orbital’s innovative engine are based on their 450cc Direct Injection two-stroke engine and a 450cc four-stroke engine.

Their engine exceeds every aspect of the four-stroke engine, more power, more torque, better power, better economy, lighter weight, cheaper to manufacture and lower emissions.

The scooter market are already using DI technology, Aprilla, Peugeot and Piaggio, as are marine and snowmobile manufacturers.

Lotus - Omnivore engine.

Lotus have been developing their own two-stroke engine using the Orbital Direct Injection system.

Their engine known as Omnivore features a variable compression ratio system, achieved by the use of a movable puck in the combustion chamber.

Norton Villiers - FITS engine.

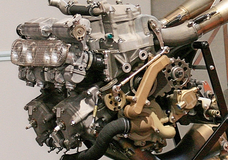

For the last 8 years they have been evolving a completely new innovative two-stroke engine design, the FITS - Forced Injection Two Stroke and has a number of interesting features and high tech components.

The engine design is currently in the patent process, however what is known is that the engine runs on plain fuel with no additives. The components are the very latest in technological design, ceramic bearings that don't need lubrication, Teflon and other coated surface treatments not yet on the market. With today's materials and engine management systems it isn't surprising to see renewed interest in two strokes.

The FITS engine has more power, lighter weight and fewer parts than four strokes and extremely low emissions.

It's being developed with diesel and bio fuel variants and will be adapted for use in a wide variety of applications, everything from chainsaws and all types of transportation.

The engine is supercharged by a Norton Villiers system giving controlled, outstanding, advanced power output over any of its rival engines. The engine has a Norton Villiers unique variable scavenge system giving reduced emissions that meet the current and impending lower emission levels being introduced by the E.U.

They say their only competitor or rival is a company in the USA which is developing an engine known as the OPOC. Norton Villiers claim the OPOC engine is much more cumbersome than theirs and thus would have limited applications.

Ecomotors – OPOC.

The primary claimed advantage of the Opposed Piston Opposed Cylinder engine is high power density and fuel efficiency, improvements of 50 per cent over current spark-ignition engines.

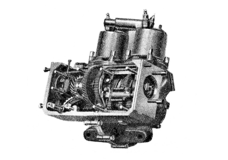

The Ecomotors engine consists of two cylinders, within each cylinder are two pistons that are linked to a common crankshaft. The pairs of pistons oscillate back and forth with a common combustion chamber between them, with each piston exposing only the intake or exhaust ports.

Nissan - Outboard TLDI.

Nissan Marine a division of the Nissan Motor Company Ltd produces a range of Direct Injection outboard two-stroke engines!

More about Orbital, pioneers of the better two-stroke.

Orbital has revolutionised the two stroke resulting in a new breed of two stroke engines that offer better power, better economy, lighter, smaller and cheaper to produce.

The result being that many companies are taking out Orbital patents or attempting to develop their own advanced two-stroke system and a few manufacturers are now producing Orbital based engines.

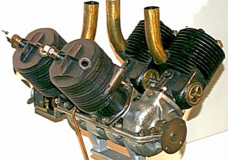

Orbital’s air-assisted direct injection technology (ADI) separates oil and fuel, keeping oil out of the combustion process and surrounding the fuel vapour in a plume of air which allows clean combustion in the short time the two-stroke cycle allows. The injection of the charge happens after the exhaust port is closed, so none is lost, and because the air injection is so effective at atomising the fuel, injector pressure can be lower – meaning the injector themselves can be cheap; far cheaper than the diesel injectors in your car which run at up to ten times the pressure. Orbital’s computer-controlled ADI cuts oil consumption by 80% and fills out the two-stroke’s torque curve to four-stroke-beating levels, it also dramatically reins in fuel consumption.

Future two-strokes will have capacities on a par with four-strokes, allowing a milder state of tune than that which earned them their peaky reputation. The result trounces the four-stroke for power, torque, flexibility and even service intervals says Orbital – whose experimental (and under-developed) 450cc single-cylinder two-stroke produced these curves against a rival 450cc four-stroke. The stroker also proved smaller and lighter, cheaper to build, less thirsty and with identical emissions.

Orbital earns royalties on every ADI-equipped engine produced, and spent the nineties and early 2000s focusing on mass-market small-capacity utility machines and courting automotive firms. But it’s since entered into partnerships with high-performance bike manufacturers it says will bear fruit soon. Big fruit: “We’re testing a 1000cc engine with performance up to 200bhp and 118lb-ft per litre with performance anywhere and completely emissions compliant” says Ahern. Who those partners are Orbital won’t say, though an ADI-equipped EXC300 from KTM is strongly rumoured. but what it will say is telling: “Everyone, except Honda, is harbouring significant two-stroke thoughts” says Ahern. That’s no wonder, says Harold Bartol, two-stroke engineering luminary and technical director of KTM’s grand prix activities: “When I look at two strokes I see only advantages – the power, the weight, the cost and less complex. If I were making a sportsbike for the road I would choose a 500cc V4 two-stroke. I have absolutely no doubt it would be superior to the current superbikes, and be possible with existing legislation.”

Honda have a huge wealth of innovative two-stroke technology but they made a controversial boardroom decision to turn their back on two-strokes for the sake of the four-stroke. This is despite the claimed superiority of ‘the new breed of two-strokes’, it may very well be that Honda and other big makers will oppose these new engines and try to prevent them from becoming a mass consumer power unit, that is the question?

Dave Blundell of Lotus: “There are lots of very pro-two-stroke engineers at Honda, and they’ve done incredible work in the field, but within the firm it’s become regarded as disloyal to support two-strokes. Their influence is so massive it’s distorted the truth about the engineering.” The truth which even Honda knows says Aprilia’s Mike Ambler: “That two-strokes can be at least as clean, and more fuel efficient than a four-stroke – their own benchmark tests with ADI-equipped two-strokes against their best four-strokes proved it.” Orbital’s Ahern: “10 years ago from an emissions point of view two-stroke and four-stroke engines were chalk and cheese. Honda’s marketing department went into overdrive and stayed there.”

With oil and fuel separated, injection computer-mapped and the mixture air-blast assisted, the new breed of two-strokes won’t recognise their smoking, spluttering, peaky forbears. They may not resemble them in capacity either. Orbital now believes two-strokes of comparable capacities to four-strokes, running at a less frenetic pace, offer the best combination of explosive two-stroke power, and flat ’n’ fat four-stroke torque curve.

Aprilia the Italian holder of 33 two-stroke world-titles has twice since 2000 come close to reviving production an Orbtal version of its iconic RS250. Ultimately it plumped for the safer option of diversifying into four-stroke middleweights, but says the door remains open: “As long as there are customers looking for the fun and the thrill of a 2-stroke engine, Aprilia will continue to meet their demand by developing models, and is keeping close tabs on what it sees as a recent revival of interest in the 250 class. If this trend should be confirmed we will take action. Of course in Aprilia style, that means passion and performance” says product director Francesco Polimeni.

Jeremy Bowdler, "I've ridden the future". Mr Bowdler is the editor of Australia’s Two Wheels magazine and the only man outside Aprilia to ride the RS250ADI – the Orbital-equipped next-generation Aprilia RS.

“It was Aprilia’s DiTech-equipped [Aprilia’s brand name for ADI] SR50 scooter that first got me thinking about the potential of an RS250. Jeez it was fast. I started pestering the local Aprilia distributors about giving Orbital an RS250 to play with, and eventually they let slip that there was, indeed, a RS. Eventually – after a long and difficult negotiation – I was not only allowed to see the bike, but I was also allowed to ride it. In the car park, but at least I was riding something that didn’t exist, officially.”

A long discussion with the guys from Orbital, from sales and engineering, ensured that I would never, ever, ever mention the bike’s existence. So here goes: With the DiTech system the RS could run on various fuel maps, well before the variable fuel injection maps offered by today’s sportsbikes, and the engineers could build almost any power characteristics into the engine, short of an S-shaped power curve.

The proof was in the pudding. After a couple of laps of the carpark on a stock bike I then rode the RS DiTech, not a puff of smoke to be seen. The best description I can give is that it felt just like a four-stroke, pulling off the bottom end without any clutch slipping or two-strokiness. The noise was deeper, sort of halfway between a two and a four-stroke but the breadth of the powerband was what really impressed. Just a steady stream of non-peaky power, I was excited. As an aside, one of the engineers mentioned he could triple the range of a four-stroke dirt bike quite simply, without any need for a large tank..

KTM in 2008 announced record sales of 25,000 two-stroke bikes and says it sees no end to the high-performance two-stroke. Stefan Pierer, the KTM CEO: “We have never let up on the development, the potential is by far not exhausted.” Spokesman Thomas Kuttruf expands: “We cannot see an end to two-stroke developments, and we intend to develop the 2-stroke advantages further. In terms of efficiency, weight and complexity you have to consider the 2-strokes in general for future sports projects, on and off-road. We have people in R&D who believe they can make them cleaner than four-strokes”. We’re expecting an Orbital air-assisted direct injection, torque-laden EXC soon.

Mira is part of China’s state-owned giant Jialing Motorcycles and has a contract with Savice, a New Zealand engine R&D firm, they are to develop a range of new direct-injection sub-250cc two-strokes designed to leave Europe and Japan’s rivals feeling heavy and flat, the deal is a two-way street, with Jialing manufacturing Savice’s line of Mira-branded two-stroke bikes with further projects already sketched out, taking advantage of Jialing’s huge economies of scale. Savice's Managing Director Denver Lawson says: “We’ve got a 1000c two-stroke V-twin modelled that’s good for 220bhp while still running Euro-3 compliant, a 62bhp 125, a completely new technology diesel two-stroke scooter engine, new piston designs allowing us to run up to 11,000rpm, split intakes. There’s a lot going on.” www.miramotorcycles.com

Lotus and Ricardo both have flagship two-stroke engines on the test bench. Emissions laws dealt a mortal blow to the performance two-stroke in the seventies and eighties, but it’s something other than technical realities that have kept the lid on the coffin, according to Dave Blundell of Lotus Engineering: “Any two-stroke can be made clean enough to pass current emissions standards thanks to Orbital’s air-assisted injection. But manufacturers have invested unimagined billions in four-stroke and they’re very happy for people’s prejudices about ‘dirty, peaky’ two-strokes to remain.”

Ricardo’s 2100cc 2/4SIGHT experimental engine is able to switch from 2-stroke to 4-stroke operation. It uses a 2-stroke cycle to meet demands for high torque and 4-stroke for constant-throttle running. In tests the engine has hit 165lb-ft per litre in two-stroke mode.

Outboards and snowmobiles.

The outboard motor industry had to comply with the U.S. Environmental Protection Agency regulations in 1998, resulting in most manufacturers quickly converting to four-stroke engine designs, but they received backlash almost as fast because engines were heavier and more expensive. Virtually all outboard manufacturer now offer both two and four-stroke engines.

In 2006 the snowmobile industry also had to comply with environmental regulations, Bombardier's Ski-Doo already had its 600 H.O. SDI two-stroke engine on the snow for two years, it was considerably cleaner than the regulations required and it achieved industry-leading fuel economy. The engine was light, powerful, dependable and clean.

Bombardier Inc is a Canadian multinational aerospace and transportation company and is the parent company of the leading outboard motor firm Evinrude, a manufacturer that sells at the premium performance end of the marine market, the one manufacturer that stayed exclusively with two-stroke engines for its outboards. Other companies that are part of the Bombardier family are Sea-Doo, Ski-Doo, Lynx, Can-Am and Rotax.

Evinrude’s E-TEC direct injection system was developed to meet the necessary emission standards while providing less weight and good performance and fuel economy at a lower cost than competing four-stroke engines.

Their 25-300bhp two-strokes offer more power, better economy and less weight and said "we've given up on four-strokes." They’re also emissions compliant to projected Euro 2010 standards. Spokesman Mike Loach says: “There’s a place for four strokes – doing the dull jobs. They’re bloody heavy and don’t give the power or the torque of the two-strokes. We believe two-strokes are simply better and people who try them quickly agree”, but Loach warns that the four-stroke mafia loom large: “The misinformation that’s spread about two-strokes goes right up to government. It’s a serious threat to our business, and we have to confront other manufacturers’ propaganda all the time.”

Now, virtually every outboard manufacturer offers both two- and four-stroke engines. The one manufacturer that stayed exclusively with two-stroke engines for its outboards is BRP and its Evinrude brand. The E-TEC direct injection system was developed to meet the emission standards while providing less weight and good performance and fuel economy at a lower cost than competing four-stroke engines.

When U.S. Environmental Protection Agency regulations for snowmobiles started in 2006, Ski-Doo already had its 600 H.O. SDI two-stroke engine on the snow for two years. It was considerably cleaner than regulations required and it achieved industry-leading fuel economy. The engine was light, powerful, dependable and clean.

As the Bombardier Recreational Products (BRP) Evinrude group developed the E-TEC system for its outboard motors (BRP acquired Evinrude in 2001), it became clear that this technology could translate directly to Ski-Doo snowmobiles. In the winter of 2008, Ski-Doo released the 600 H.O. E-TEC engine. Is the E-TEC engine a big deal in the world of snowmobiling? Absolutely, it demonstrates that the two-stroke engine — with all of the advantages it offers for snowmobiling — is far from being axed from snowmobile manufacturers’ product plans. The 600 H.O. E-TEC is available across Ski-Doo’s 2009 line up and further expansion of the direct injected technologies will prove the strength of the two-stroke engine design and its attributes.

The U.S. Environmental Protection Agency (EPA) imposed emission restrictions on snowmobiles in 2006, which put limits on the levels of carbon monoxide (CO) and hydrocarbons (HC) that could be present in the exhaust. There was no imposition of what type of engine manufacturers could use. If a two-stroke engine could run clean enough to meet the regulations, it would be accepted. Have a look at this 2 stroke versus 4 stroke video. http://www.evinrudenation.com/reviews/the-fuel-duel-are-4-strokes-more-efficient-than-2-strokes/

Other Direct Injection Systems. Following the early 1990’s Australian Orbital’s development of a two-stroke automobile engine that met then-current U.S. emissions requirements, exceeded the four-stroke fuel efficiency numbers, weighed almost 200 pounds less than a four-stroke that produced similar power, vibrated less than an equivalent four-stroke and cost from $300 to $500 less to manufacture. Needless to say, it got the US transportation industries excited with Orbital’s development.

Ford Motor Company, General Motors, Mercury Marine, Outboard Marine Corporation, Polaris Industries, Bombardier and likely many other engine manufacturers soon bought patent licenses to use Orbital’s concepts for clean two-stroke development programs.

Automobile companies around the world have launched direct-injection projects, many of which don’t include Orbital’s design. The variety of concepts being developed is impressive and each one seems to confirm the ability to overcome the perceived two-stroke bug-a-boos of suffering from poor economy and high emissions.

Mercury Marine uses Orbital technology in its two-stage, direct-injection two-stroke outboards. The Dodge Neon car was originally stated to have a direct-injected, two-stroke engine, but development of the engine was delayed and a small four-stroke went to production.

Polaris has license to the Orbital patents and has been working on two-stroke engines that are cleaner than its current Cleanfire semi-direct injection systems. Arctic Cat is committed to two-stroke engine designs for its snowmobiles and it is working on direct injection designs.

Yamaha builds two-stroke outboards with High-Pressure Direct Injection (HPDI). The 200 HPDI engine has twin, high-speed fuel pumps that pressurize the gas up to 1,000 psi, and then inject the fuel after the exhaust ports are closed. The system is similar to injection systems on diesel engines.

Car manufacturers research continues by companies that have purchased patent licenses to use Orbital’s technology, GM, Ford and others have developed two-stroke designs of their own. Most of these engine designs utilize crankcase scavenging (crankcase pressure is used to push exhaust gasses out of the combustion chamber) and total-loss lubrication systems (oil essentially becomes part of the fuel charge). All designs scavenge the cylinders only with air, incorporate some means of varying the exhaust timing, include a multiple-chamber cylinder head and utilize air-assisted fuel injection. French automaker Peugeot and its concept two-stroke engine incorporates a poppet valve that seals a pre-combustion chamber until fuel is delivered. Rather than use a separate air pump to supply the air-assist for injection, Peugeot has placed a second reed valve in the crankcase that allows air to escape into a chamber, which is then used to assist the air for injection.

Chrysler and Subaru have both developed two-strokes that stray further from the traditional two-stroke concepts. Rather than use the crankcase as the scavenging pump, they both use a belt-driven blower or supercharger to scavenge the cylinders. The crankcase remains a wet sump design like most automobile engines.

Transfer ports carry the air to the cylinder and the piston handles the valving of the ports. In Subaru’s design, an exhaust port in the cylinder is opened and closed by the piston, but just downstream of the port is a rotating valve that boosts the cylinder charge to more than atmospheric pressure. Air assist isn’t needed because the 1,000 to 1,200 psi fuel pressure rating automatically atomizes the fuel as it leaves the injector nozzle.

The biggest most complex and heaviest of the conceptual automotive two-strokes is Toyota’s design. The engine is basically one of the company’s dual-overhead cam, four-stroke engines converted to run a two-stroke cycle. The camshafts run at crankshaft speed and air is delivered to the intake valves through a supercharger. Fuel is added through a high-pressure, direct-injection system. An in-line, six cylinder, 244 cubic-inch version of this engine is said to produce torque equal to GM’s 454 V8.

The motor vehicle industry has invested in a lot of two-stroke development and it’s not done. The success of the low emission two-stroke engines of today will suggest what will happen tomorrow. Will we see new two-stroke designs take over in the dirt bike market again? Will new two-stroke designs power ATVs again? Will Yamaha adapt its outboard HPDI system to snowmobiles? Who knows?

What I do know is that the new, clean two-stroke engines of today outperform the four-strokes in almost every category of performance with less weight and fewer complex, moving parts.

Can the two-strokes, with their impressive specific output, high power-to-mass ratio, and package benefits, hold their own against the four-stroke assault?

Although two-strokes are now a rarity on the road, there are some applications where there has been a resurgence and that is in motorcycle off road events, other applications where two-strokes engines are used is in the Snowmobile and Outboard motor market. Tremendous development has taken place with manufacturers now producing many sophisticated devices. being produced Bombardier believe they can, the evidence is the recently unveiled Rotax E-TEC 800R, newly equipped with direct fuel injection (DI) and for 2011 Ski-Doo sleds. (BRP owns Rotax, Ski-Doo, as well as Evinrude marine engines and Sea-Doo watercraft.)